When I first acquired this comptometer from a local thrift store several years ago, I'd noticed the worn keycaps, indicating years of long fingernails on keys (there's even a hint of red fingernail polish on some), but didn't understand at the time why only the 1 through 5 keys showed this wear, nor why the 3 keys seemed especially worn. Now I understand.

Then I located this

archived scan of the book How to Use the Calculator and Comptometer, Third Edition, by James R. Meehan, distributed by Gregg Publishing, and finally sat down today to read up on the formal method of comptometer use.

As it turns out, the book teaches a "touch method" whereby the first and second fingers of the right hand are located on the 3 row - the home row - and the fingers are permitted to reach from the 1 to the 5 keys. For addition and subtraction, numbers larger than 5 are entered in a two-step process; for example, 7 is entered by pressing 4, then 3, in rapid succession. It may seem slower than directly entering the 7, but this method enables the user to enter these numbers by feel, keeping one's eyes on the work at hand, and thus ends up being faster in practical use.

This explains the wear on only the 1-5 keys, and the excessive wear on the 3 row. The user(s) of this machine (my sample dates back to ~1915) obviously were schooled in use by the Gregg method, which I find very interesting.

I should also mention that the odd-numbered key caps are dished in, while the even key caps are flat, making it easy to navigate the keyboard by feel.

Okay, but is using this machine any faster than a crank-operated adding machine of its day, or a modern electronic calculator (or computer keyboard) of today? I can say without a doubt yes! The Gregg method requires the use of the first and second fingers of either or both hands, and the entire number is entered in at once, parallel fashion. Emphasis is made on using the correct fingering technique for efficient number entry; the fingers hover over a group of keys to form the number being entered, and they are all pressed down at once. Being a "key operated" adding machine means as soon as the keys are pressed the calculation is performed and the digits in the register dials immediately indicate the result, real-time, as the calculation progresses, by means of the machine's internal planetary gear mechanism. This is the difference between a comptometer and a lever-operated adding machine.

By the way, the lever on the right side of the Burroughs machine is for clearing the machine, not for number entry.

For example, to add three 3-digit numbers, the right hand forms each number in turn and makes three rapid presses of the keys, which takes less than two seconds. I can't do this same sequence of operations (adding three 3-digit numbers), using a conventional electronic calculator or keyboard, nearly as fast. The difference in speed is amazing.

Subtraction uses the smaller sets of numbers on each key, which are the 9-complements of the main numbers, and the technique is to enter the complement number that's 1 less than the actual number being subtracted. For example, to subtract 18, the user simultaneously presses the 8 and 2 keys on the tens and units columns, which corresponds to the 1 and 7 complement numbers (i.e. 1 less than 18). In practice this is entirely intuitive and easy.

I'd already grasped addition and subtraction before I found this manual online, so what I was interested in was discovering how multiplication and division worked. Would they be difficult and time-consuming to learn? Surprisingly, no. Multiplication and division use the entire keyboard; numbers larger than five are entered directly, rather than broken up into smaller numbers like with addition and subtraction. In multiplication the user enters the larger of the two numbers being multiplied (the multiplicand) and, starting at the units column (it can be done in either order) presses the number into the keyboard that number of times corresponding to the units number of the multiplier. Then the user shifts the fingers so the same multiplicand number starts at the tens column and presses it in that number of times corresponding to the tens digit of the multiplier, etc.

For example, in the problem of 357 times 24, the 357 is held over the keyboard starting at the ones column and pressed in 4 times; then the fingers are shifted one column to the left and that same number is pressed in 2 times, for an answer of 8568. In practical use a three digit number times a two digit number can be done in about 3 seconds. I can't do it that fast on a modern calculator, no way.

I won't attempt to describe in words how division works, but suffice it to say that it's quick and easy. I plan on making a video about this soon, if you're interested; but in the meanwhile check the link above to the instruction manual for details.

I will say this: I've kept my Burroughs comptometer stored away to protect it from dust and because of its size, as it takes up a sizable footprint on my desk. But also, up till now I'd only known how to add and subtract, whereas I frequently have need for multiplication. Now I can see the possibility of using it for more practical purposes in my daily life, and that's exciting.

I've just received this book today and haven't yet delved into it, but there are lots of fun party tricks a person can do with the humble pocket calculator. I was inspired to get this book by a fond memory, from back in the 1970s, of a book called Games Calculators Play; back when these were new gadgets and I'd begun to amass a small calculator collection.

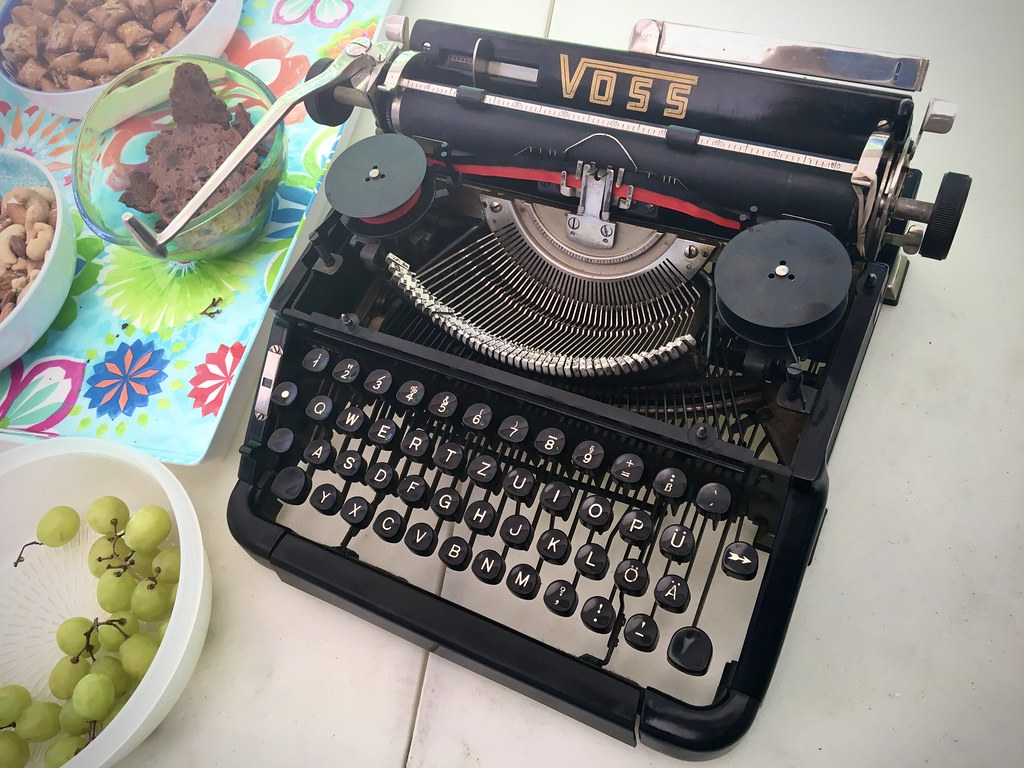

I'm really enjoying my Voss Modell 50 typewriter (used to type this piece), now that the imprint smudging and ribbon issues have been resolved. The smudging was caused by the carriage tripping right as the character was being printed, and required an adjustment to the escapement timing. These Voss typers have more adjustments than I've seen on many other machines, making it easy to resolve these kinds of problems. Also, the keyboard is a bit wider than many other medium sized portables, and there's ample clearance between the "A" key and the shift lock; touch-typing is therefore a breeze.

I was also enjoying typing on this vintage, slightly yellowed, notebook paper, which lends an immediate aged look to the piece. I need to find more of this old paper.

Stay well and do something creative!

Labels: Burroughs, calculators, Voss Modell 50