Direct Positive Print Experiments

Exposure: 1/8 second at f/5.6 in morning light

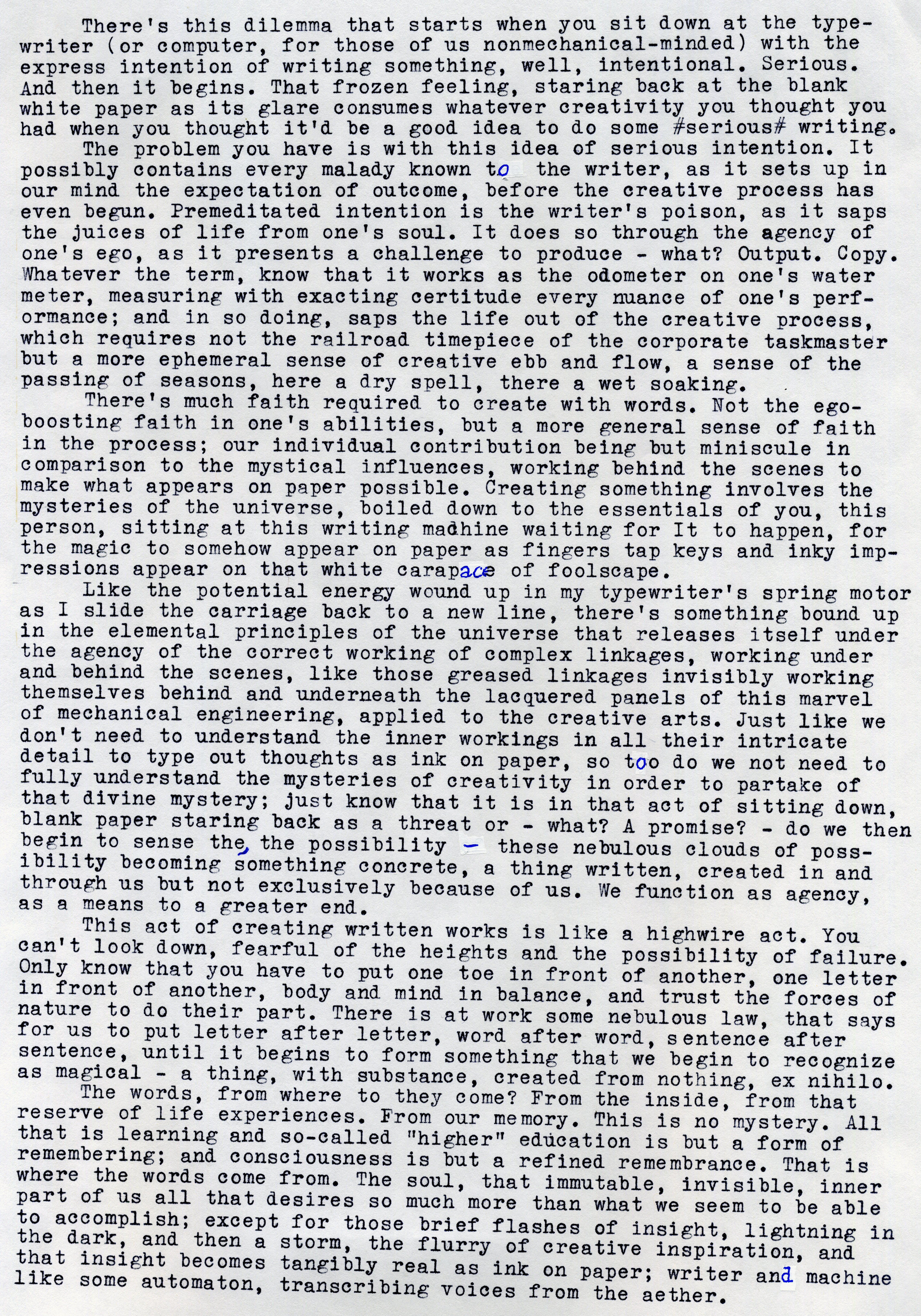

Exposure: 1/8 second at f/5.6 in morning lightThere was a time, only a year or so ago, when I took for granted that Harman's Direct Positive Paper would be available for us creatives to use. But it seems that change is the only constant in life. In case you haven't heard, Harman/Ilford have been experiencing manufacturing difficulties with their direct positive paper and so, for the time being, it is no longer available.

So, what is direct positive paper? Think of it as a wet-processed Polaroid print. You fit sheets of the fiber-based print paper into your large format camera's film holders, expose it as a very slow-speed film, then process it in standard black-and-white print chemistry (developer, stop bath and fixer) to get a one-of-a-kind, fiber-based positive print. Were you to do that with conventional black-and-white printing paper, you'd end up with what we call a paper negative: a photographic negative on a paper supporting medium. Harman's Direct Positive Paper represents a kind of hybrid process, combining the best of modern chemistry with traditional alternative photographic processes.

There have been methods for creating such direct positive prints in the past, using exotic and dangerous chemicals in what is termed a reversal process. This is what happened inside those old-fashioned photo booths, the ones that spit out a strip of black-and-white prints. These traditional reversal processes used a dichromate-based bleaching compound and chemical fogging agent to do the reversal part of the process. Theoretically feasible at home, yes, but impractical for most of us and requiring considerable care in handling, storage and disposal of chemicals.

Several weeks ago, through some fortuitous Internet surfing, I happened upon several blog posts that describe a different chemistry for achieving the chemical bleaching part of the reversal process. Rather than using toxic chromic acid-based compounds, the method described uses hydrogen peroxide and citric acid. Armed with little more than these blog articles to go on, I decided to try my hand at it.

The first step was acquiring a more concentrated solution of hydrogen peroxide than the 3% topical solution found in the drugstore. The blog articles describe using a 9% solution in the bleaching agent formula. I was able to source a local supply of 35% hydrogen peroxide at the same place as the citric acid powder, strong enough to be diluted down for my purposes.

Pause must be made at this point to remind anyone contemplating doing this that, although this new formula isn't toxic like chromic acid, concentrated hydrogen peroxide deserves to be handled with respect, as it is a strong oxidizing and corrosive agent, will do direct harm to your body if it makes contact and will react violently with many flammables, including spontaneously combust. You must wear protective gear on your exposed skin, including shielding your face and eyes, (and think about protecting your legs and feet if something erupts at table-height) and mix it only in a safe location, away from flammables and other corrosives. This warning is not intended to scare you off from considering doing this process, only as a common-sense precaution, since the laws of physics don't care who you are.

I purchased a 1 liter plastic bottle, which was kept refrigerated at the store. I therefore decided to store my bottle also in a refrigerator, which helps reduce its reactivity during storage and prolongs it shelf-life.

The basic reversal process is this: develop the exposed paper in standard paper developer, then a quick rinse or stop bath. Next is the bleaching bath, in this case comprised of a dilute hydrogen peroxide solution with citric acid added. Next is a quick rinse, then the front of the paper is squeegeed dry, and the paper is then exposed directly to a bright source of white light, to fog the remaining unexposed silver halides in the emulsion. Then the paper is developed, stopped and fixed as normal. These last steps, from the fogging to the fixing, can be done in normal room light.

How the image reverses from a negative to a positive is that the bleaching agent acts selectively only against the developed metallic silver, produced by the first developing step, that represents the highlights of the scene. These dark silver molecules are bleached near paper-white, while leaving the unexposed silver halides intact in the remainder of the emulsion. Then the fogging with light exposes those remaining silver halides which, after the second development, turn into dark metallic silver and represent the shadow portion of the image.

The articles reference using a pH meter to accurately determine the acidity of the bleaching agent. Since I don't have such a device, I decided instead to employ empirical testing. I used Freestyle Photo's Arista grade 2 RC paper, initially rated at an ISO of 3 (I normally rate this paper at ISO 12 as a paper negative; it seems the reversal process requires a denser latent image to work properly). I mixed a 300mL solution of bleaching agent using 77mL of 35% peroxide and 223 mL of water, to which 2 teaspoons of citric acid powder was thoroughly dissolved. This amounts to a 9% concentration of hydrogen peroxide. To do this safely, I performed the mixing out doors, wearing protective gear, diluting the peroxide into the water, thoroughly stirring, then adding the citric acid powder after, with more stirring.

For my initial tests, at ISO3, I developed the paper for 2 minutes, bleached the paper for 5 minutes, fogged the paper under bright light for several minutes, then finished the process with a 2 minute develop, 30 second stop bath and 2 minute fix (pretty standard times for developing print paper). My developer was Ilford Multigrade concentrate diluted 1:15. After the bleaching step I rinsed the paper and turned on the white lights. The paper had a negative image with an irregular brass-colored mottling. Fogging the paper with direct exposure to light didn't change its appearance. But it did dramatically change when put back into the second developing bath, where the image quickly went from negative to positive.

Though the results were promising, the contrast was very low and the intensity of the highlights was very muted. You'd need to view the print under bright illumination to see the image with any kind of clarity. I next decided to add more citric acid to the bleaching agent, but the results didn't improve.

So I decided to make two changes at once: 1) increase the exposure by reducing the ISO to 1.5 (since my new meter only goes down to ISO3, I simply used the next slower shutter speed); and 2) double the concentration of hydrogen peroxide, from 9% to 18%. It turns out that this makes mixing the bleaching agent more convenient, as I can mix a 1:1 solution of 35% peroxide with water. So 150mL of 35% hydrogen peroxide to 150mL of water, plus 2 teaspoons of citric acid powder, makes the new solution.

The results are very promising, as evidenced by the above image. Coming out of the bleaching agent the highlights were already reversed white, even before the light fog and second development; it seems the bleaching agent activity determines the highlight density. The print has a nice warm tone to it, although the background shadows have a somewhat mottled appearance, evidencing its experimental nature. Held in hand, it's not much different from the Harman paper, other than color tone and the RC paper's surface finish. In processing this print, I reduced both development steps to 1:30, reduced the bleaching step to 2 minutes and the fogging step to 1 minute under a strong LED lamp of 5000k color temperature. I use the same developer tray for both development steps, to make things more convenient; which works well as long as you remember to thoroughly rinse the paper after the bleaching step.

It's not as convenient up front to process print paper this way, as compared to the Harman Direct Positive paper. But what you use in time up front you save on the back end of the process, since the RC paper only requires a brief rinse aid treatment and 5 minute wash, then can be quickly dried to completion, using a squeegee and hair dryer. Contrast this with fiber prints, that require an hour of rinsing and hours of drying time, taped flat to a sheet of glass to prevent curling.

I'm excited to try this process with other RC papers in my collection, including multigrade warm tone papers with a luster finish. I might also try increasing the concentration of peroxide to about 20-25%, and see what effect it might have on the results.

I'll be happy when Harman/Ilford returns their direct positive paper to the market, for the sake of others who would like to dabble in this interesting alternative process but don't want to get more involved than standard print chemistry. For myself, I'm grateful that this shortage has forced me to seek alternatives, as it has opened up a new avenue for my creative expression.

Post-Script: There is a photographic paper called Galaxy Direct Positive Paper which has entered the market recently. Despite its name, it does not produce a direct positive image in standard print paper chemistry, but rather requires a reversal process, like what I've described above. Still, I'd like to try it out, since it's supposedly very similar to the old photo lab print papers and has a thicker, more silver-rich emulsion.

Labels: Harman DPP, reversal processing