No, the thermal Sharp PA-1050 typewriter prints lines just fine. I'm using the iPhone's panorama mode to scan this over-24-inch-long piece, and handholding it as I move it causes these wonky artifacts. I need to make a dolly that moves the iPhone smoothly across the tabletop. Also, maybe less coffee?

Side view (above). Note the narrow gap between the main plate and bottom, where the paper feeds under the unit from the supply spool in back to the writing surface and take-up spool up front. The supply spool free-wheels on the aluminum rod, whereas the take-up spool is driven by turning the wing nut. Note the half-round dowels at the front and rear edges for the paper to make a smoother bend around.

Underside (above). Note the access holes for feeding a fresh roll of paper. And the non-slip rubber pads.

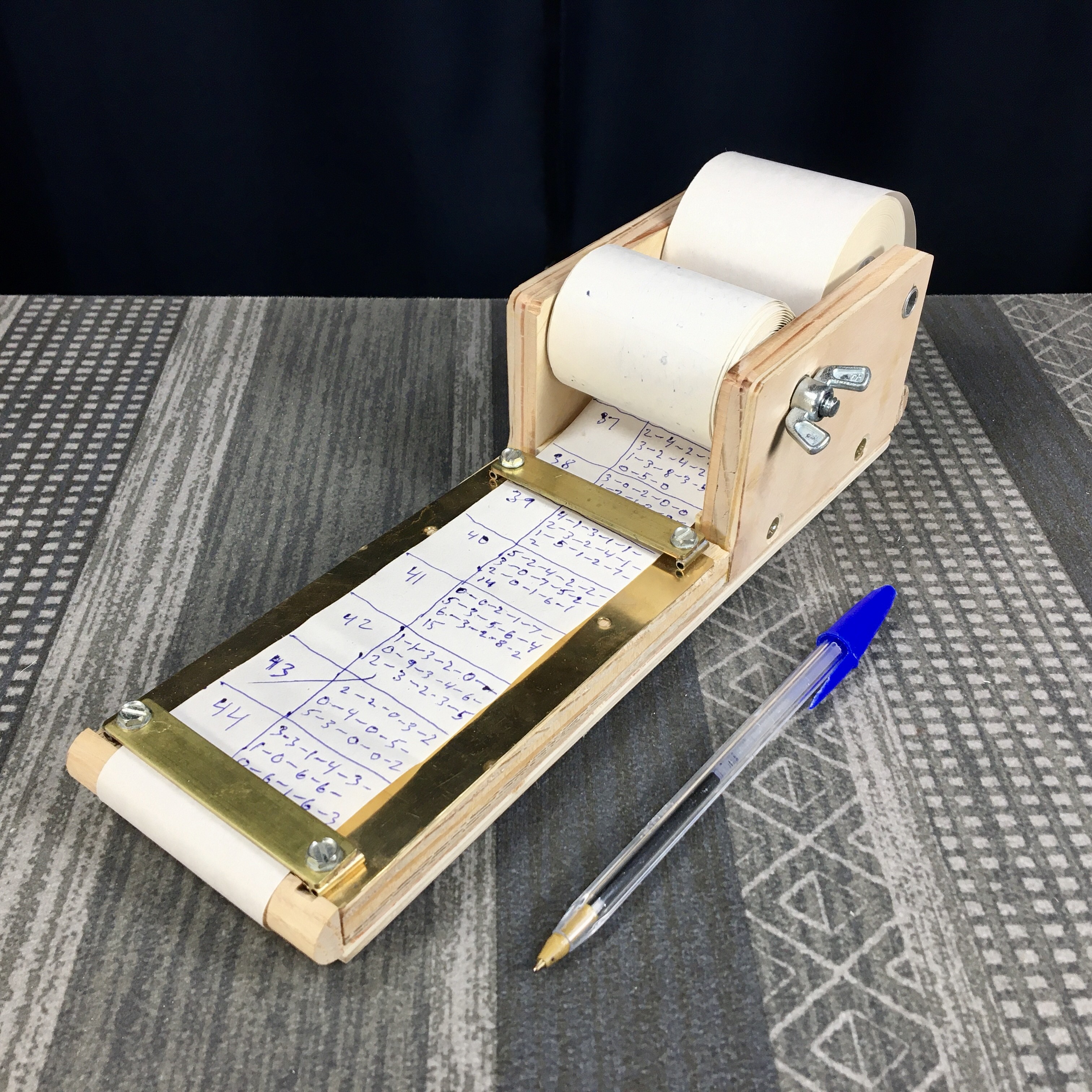

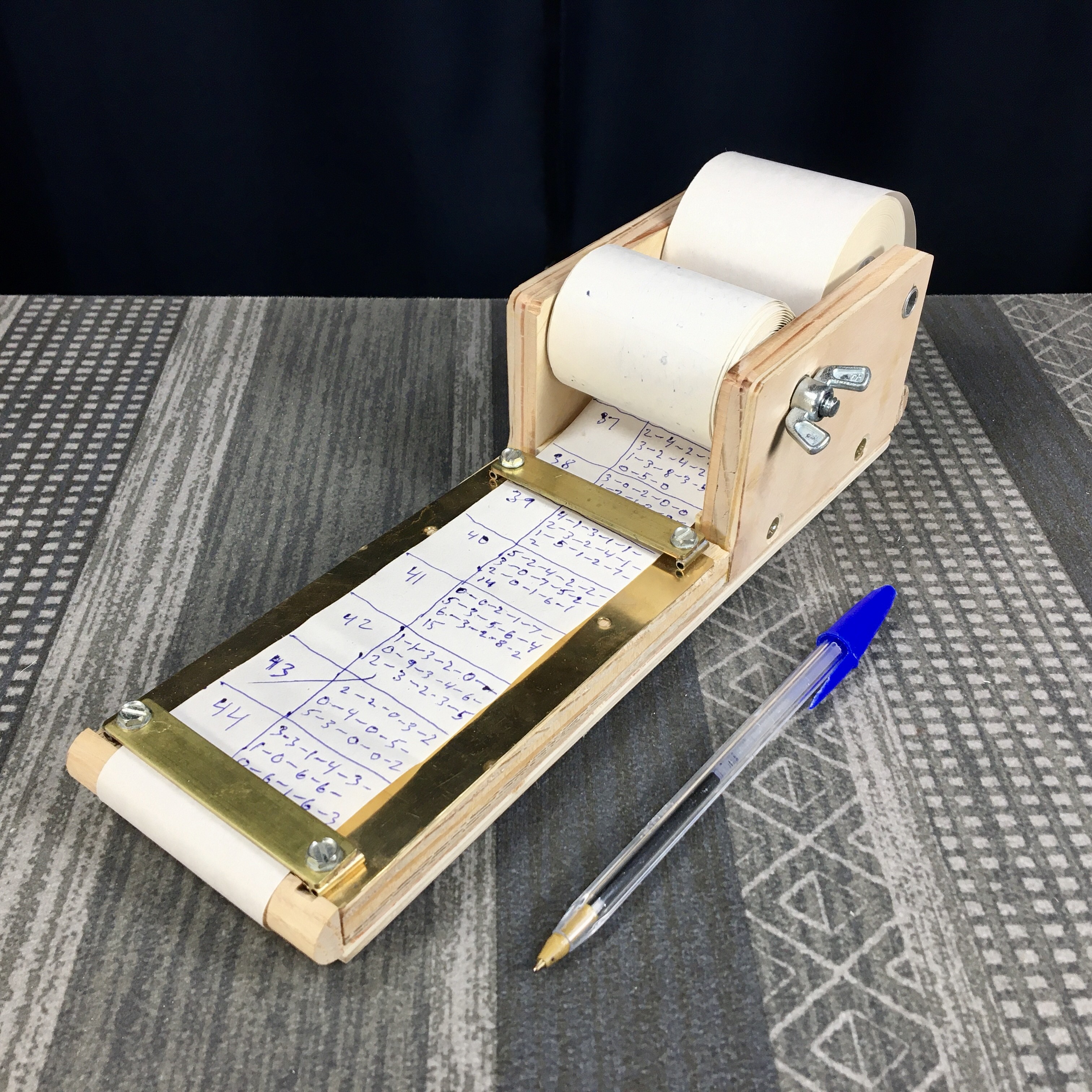

For reference (above) is the note-taking roll holder I made for my wife. Simple design, the roll free-wheels on the aluminum tube. The thin brass rod is for the paper to roll underneath. Note the brass plate that serves to keep the paper flat while providing for a tear-edge. The version I made for my sister-in-law is very much the same. To replace the paper, the aluminum tube is pressed out with a pen cap, and fits snuggly into the holes drilled in the side brackets.

Let's get back my comment above, about using the iPhone's panorama mode for "scanning" this long piece, thermally-typed on a roll of fax paper. Panorama mode is intended for the user to hold the phone vertically in portrait orientation and slowly rotate around a scene; the phone's software stitches together a mega-sized image, much larger in pixel size than the native camera could achieve on its own. In fact, a standard flatbed scanner would also be of little use for these long sheets of paper.

In use as a makeshift scanner, I'm instead moving the phone in a line along the length of the scroll of paper. In order to have a distortion-free image I need to move the phone at a constant speed, without it tilting up, down or sideways. And, in order to achieve even exposure along the length of the paper, I need to lay it on my video table with lights ablaze. For this shot I clipped the paper sideways to a board and tilted it at an angle toward the phone; the phone in portrait orientation needed to be pointing down at an angle perpendicular to the paper, then be moved smoothly along its length at a constant speed without changing the angle. Not easy to do. In the future I need a fixture to help me do this better.

I'm one for the "elegant solution". Yes, I could cobble together a stepper-motor-and-Arduino system for moving a motorized dolly across the tabletop, or buy a video slider system, but I'm thinking of an elegantly simpler solution. First is a smooth surface that runs the width of the table, say made from spare hardwood flooring panels that happen to be in my storage shed. Next is a wheeled dolly to mount the phone onto via an adjustable ball-head mount. Then a thin wire (or string) that runs from the front of the dolly to a pulley at the side of the table, attached to the end of the string being a heavy weight, that pulls the dolly forward as the weight falls. To achieve constant speed another string is attached to the back of the dolly, around another pulley and onto a weathervane-style rotor. As the weight pulls the dolly, the weathervane rotor spins fast. Because of air resistance, the rotor can only spin at a constant speed, which helps to regulate the speed of the dolly's movement.

I first saw this method used in a Panasonic (Technics) cassette deck, back in the 1980s. Most cassette decks that had a slow-opening lid used a plastic dashpot (a cylinder and piston arrangement with a calibrated air hole) lubricated by synthetic grease, that made the lid, operated by a spring, open slowly - until the grease hardened or the rubber o-ring wore out, which was frequent. In the Technics deck, they use a draw spring attached to the door that wound around a shaft, like a windlass, that turned a 4-vane brass whirligig. The speed of the door was regulated automatically by the air friction of the whirligig spinning. I thought it was an elegant solution that proved to be much more reliable than the plastic cylinder and grease method used by other brands.

Or, another strategy might be to put a few extra lines every 11 or so inches, and photograph the scroll in sections; but that would involve preplanning, and I'm much better with spontaneity.

PS: What's all them numbers written on the paper roll? That's the subject of another blog article!

Labels: paper rolls, Sharp PA-1050, thermal typewriters, typing scrolls